- Products

- /Flat Tempering Furnaces

- /Bent Tempering Furnaces

- /F. & B. Bi-directional Furnaces

- /Double Bent Bi-directional Furnaces

- /Variable Curvature Furnaces

- /Combined Tempering Furnaces

- /Continuous Tempering Furnaces

- /Gas Heating Tempering Furnaces

- /Cyclone Tempering Furnaces

Product Search

Heating mode:

Industry:

Products:

Project & Case

Contact Us

- Address: Guangjian Building, No.12 – Wangcheng Road, Luoyang, China

- Zip Code:

- Email:

- Phone:

- Fax:

Combined Tempering Furnaces

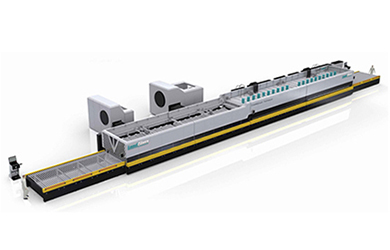

LD-AT3 JetConvection Plus Combined Flat Glass Tempering Machine

Architecture&Furniture, Automobile Industries, Household Appliances and Solar Power Industries, etc.

JetConvection heating on the top.

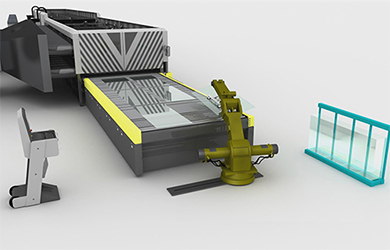

On-line and Off-line Low-E (E=0.02) Glass, Ultra Clear Glass, Screen Printed Glass, Pattern Glass, Tinted Glass, Clear Glass, etc.

Chat Online

Leave Message

- Product Introduction

- Technical Features

- Technical Parameters

- Customer Case

- In 2008, LandGlass introduced the combined flat glass tempering machine to meet the increasing quality requirements for tempered glass in the architectural and household appliances markets. The LandGlass combined tempering machine has two heating furnaces that can be controlled individually. The result is a significant quality increase that overpasses the glass quality requirements of the market.

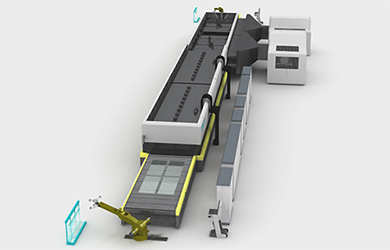

AirStreamTM Radiation Heating plays a supportive role during the process. Compressed air is injected into the heating furnace to aid the heating process of the top surface of the glass, which ensures heating uniformity for on-line Low-E glass, and other glass types.

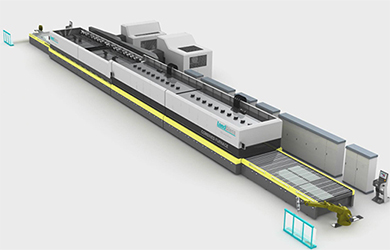

JetConvection PlusTM Convection heating plays an important role during glass heating. Air is heated in the JetConvection chamber inside the heating furnace and is blown onto the glass surfaces. Air is then recirculated and recirculated by the convection blowers into the JetConvection chamber. LandGlass Jetconvection technology enhances the quality of the final product and increases productivity by ensuring an even heating, while minimizing production costs.

LD-AT Series Combined Flat Tempering Machine is equipped with 2 heating sections, which can be installed with either AirStream or JetConvection heating technologies. The furnace can also be equipped with one or more chillers according to the quality and productivity requirements of the final product. The combination of 2 heating sections allows for an easy adaptation to each customer's needs, having the possibility to select different working modes that optimize final quality, productivity or maximum temperable size.

LD-AT3 JetConvection PlusTM Combined Flat Glass Tempering Machine has two heating sections and both heating sections adopt JetConvection PlusTM heating technology on the top.This tempering machine ensures an excellent quality and a higher performance. Glass than can be tempered includes: on-line and off-line Low-E (E=0.02) glass, extra ultra clear glass, screen printed glass, pattern glass, tinted glass, clear glass, etc. - 1. LD-AT3 JetConvection PlusTM Combined Flat Glass Tempering Machine has two heating sections with JetConvectionTM heating technology applied on the top; it can temper glass with the best quality.

2. Different working modes can be set in order to focus on quality, productivity or loading size.If the first heating section works as preheating furnace, it will reduce quality defects such as optical distortion, spherical bending, hot spots, white haze, etc.If both heating sections work as independent heating furnaces, it will largely increase throughput.If two heating sections work as one big heating section, it will be able to process extra large glasses.

3. Glass tempered by this tempering machine is suitable for the architectural, furniture, household appliances, automotive and solar industry markets. The glass that can be tempered includes: on-line and off-line Low-E (E=0.02) glass, extra ultra clear glass, screen printed glass, pattern glass, tinted glass, clear glass, etc.

Productivity is calculated on 5mm clear glass and 6 mm Low-E glass (E=0.08) with 65% loadage. Actual productivity is subject to glass types, sizes and loadage. Not all types are listed here due to limited space.LD-AT3 JetConvection Plus Combined Flat Glass Tempering Machine Types Max.dimensionMin.dimensionGlassthicknessProductivity(loads/h)Installedcapacity(KVA)ClearglassLow-E A2436T3+ 2440X3600 200X400 4-19 20-24 18-22 1400 A2442T3+ 2440X4200 200X400 4-19 20-24 18-22 1600 A2450T3+ 2440X5000 200X400 4-19 20-24 18-22 1800 A2460T3+ 2440X6000 200X400 4-19 20-24 18-22 2200 A2480T3+ 2440X8000 200X400 4-19 20-24 18-22 2800 A3050T3+ 3000X5000 300X500 5-19 20-24 18-22 2300 A3080T3+ 3000X8000 300X500 5-19 20-24 18-22 3500 - Company

Oldcastle LocationUSA Company ProfileOldcastle is the largest manufacturer of building products and materials in North America. Its tempered glass products are widely used in architectural industry, which allows it to occupy a large market share in North America. And its glass tempering machine is produced by LandGlass. Furnace TypeLD-AT JetConvection Combined Flat Glass Tempering Machine Main ProductsLaminated glass, insulating glass, fireproof glass, Low-E glass, etc.