- Products

- /Flat Tempering Furnaces

- /Bent Tempering Furnaces

- /F. & B. Bi-directional Furnaces

- /Double Bent Bi-directional Furnaces

- /Variable Curvature Furnaces

- /Combined Tempering Furnaces

- /Continuous Tempering Furnaces

- /Gas Heating Tempering Furnaces

- /Cyclone Tempering Furnaces

Product Search

Heating mode:

Industry:

Products:

Project & Case

Contact Us

- Address: Guangjian Building, No.12 – Wangcheng Road, Luoyang, China

- Zip Code:

- Email:

- Phone:

- Fax:

Flat Tempering Furnaces

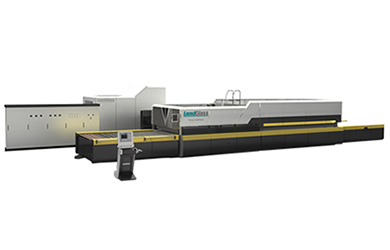

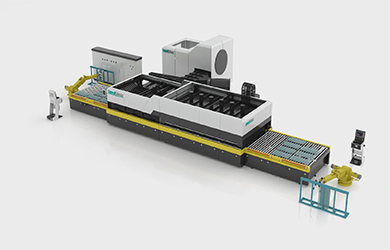

LD-A JetConvection Plus Flat Glass Tempering Furnace

Architecture&Furniture, Automobile Industries and Household Appliances, etc.

Forced convection heating on the top and bottom.

On-line and Off-line Low-E (E=0.02) Glass, Ultra Clear Glass, Screen Printed Glass, Pattern Glass, Tinted Glass, Clear Glass, etc.

Chat Online

Leave Message

- Product Introduction

- Technical Features

- Technical Parameters

- Customer Case

- LandGlass is a pioneer in R&D of forced convection heating technology. After years of theoretical research and production test, the LD-A JetConvection Plus Tempering Furnace has become the first choice for small, medium and large glass manufacturing companies. This tempering furnace is recognized internationally, and it is the core product of LandGlass.

JetConvection PlusTM Convection heating plays a main role during glass heating. Air is heated in the JetConvection chamber inside the heating furnace and is blown onto the glass surfaces. Air is then recirculated and recirculated by the convection blowers into the JetConvection chamber. LandGlass JetConvection technology enhances the quality of the final product and increases productivity by ensuring an even heating, while minimizing production costs.

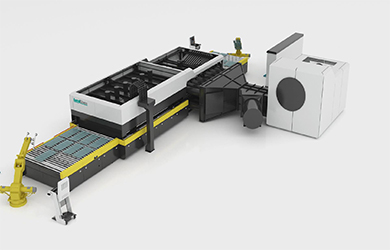

LD-A JetConvection PlusTM Flat Glass Tempering Furnace adopts JetConvection PlusTM Heating Technology. Glass tempered by this tempering furnace has the best quality and is suitable for the architectural and furniture markets. Glass that can be tempered includes: on-line and off-line Low-E glass (E=0.02), extra ultra clear glass, screen printed glass, pattern glass, tinted glass, clear glass, etc. - 1. Full convection is a completely different approach to the traditional combination of radiation heating and convection pipes. The use of full convection solves a series of heating challenges that are due to the different emissivities at the top and bottom surfaces of coated glass.

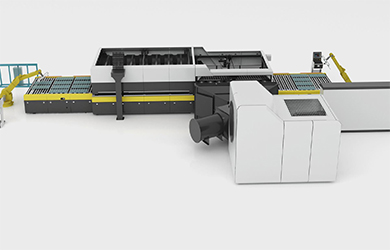

2. Our convection technology has been developed to allow for more heating zones along the width of the furnace. Each of these heating zones can be controlled separately, allowing the generation of heating profiles along the width and the length of the furnace.

3. The length of the furnace will determine the number of convectors that will be installed, each of which will be independently controlled to allow for different convection settings. Convection blowers are installed at the top of the convection box to balance the air pressure inside the furnace. The air flow distributing mechanism together with the specially designed nozzles, ensure a uniform distribution of the convective airflow.

4. The built-in optimization algorithm and the computer fuzzy temperature control modules of the PID database, together with the frequency control of the blowers, assure that both heating and frequency profiles can be customized and optimized.

5. Lower bottom heating temperature can be achieved by adjusting the convection parameters, so that the heating defects such as white haze, hot spots, etc., can be eliminated. In the meantime, heating time is reduced and efficiency is optimized.

Productivity is calculated on 5mm clear glass and 5 mm Low-E glass (E=0.08) with 65% loadage. Actual productivity is subject to glass types, sizes and loadage. Not all types are listed here due to limited space.LD-A JetConvection Plus Flat Glass Tempering Furnace Types Max. Dimension Min. Dimension Glass thickness Heating time(second) Productivity (loads/h) Installed capacity(KVA) Clear glass Low-E Clear glass Low-E A1830J+ 1800X3000 150X300 4-19 28-32 38-42 18-20 15-18 500 A2036J+ 2000X3600 150X350 4-19 28-32 38-42 18-20 15-18 630 A2436J+ 2440X3600 150X350 4-19 28-32 38-42 18-20 15-18 800 A2442J+ 2440X4200 150X350 4-19 28-32 38-42 18-20 15-18 1000 A2450J+ 2440X5000 150X350 4-19 28-32 38-42 18-20 15-18 1000 A2460J+ 2440X6000 150X350 4-19 28-32 38-42 18-20 15-18 1250 A2850J+ 2800X5000 200X400 4-19 28-32 38-42 18-20 15-18 1250 A3050J+ 3000X5000 300X500 5-19 28-32 38-42 18-20 15-18 1250 A3080J+ 3000X8000 300X500 5-19 28-32 38-42 18-20 15-18 2000 - Company

Glas Strack LocationGermany, Europe Company ProfileGlas Strack is a German enterprise with a long history more than 70 years. As a senior pioneer in the glass processing industry, it has different roles during the daily work. Besides the wholesale of glass, Glas Strack also designs and manufactures products according to the specific requirements of the customers. Furnace TypeLD-A JetConvection Flat Glass Tempering Furnace Main ProductsTempered glass, laminated glass, glass door, glass shower room, art glass, decorative glass, stained glass, etc.