- Products

- /Flat Tempering Furnaces

- /Bent Tempering Furnaces

- /F. & B. Bi-directional Furnaces

- /Double Bent Bi-directional Furnaces

- /Variable Curvature Furnaces

- /Combined Tempering Furnaces

- /Continuous Tempering Furnaces

- /Gas Heating Tempering Furnaces

- /Cyclone Tempering Furnaces

Product Search

Heating mode:

Industry:

Products:

Project & Case

Contact Us

- Address: Guangjian Building, No.12 – Wangcheng Road, Luoyang, China

- Zip Code:

- Email:

- Phone:

- Fax:

Continuous Tempering Furnaces

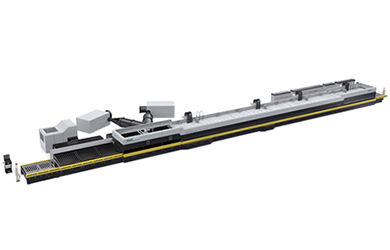

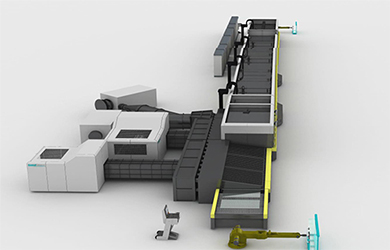

LD-AL JetConvection Plus Continuous Flat Glass Tempering Equipment

Architecture&Furniture, Automobile Industries, Household Appliances and Solar Power Industries, etc.

Combination of convection and radiation heating.

On-line and Off-line Low-E (E=0.03) Glass, Ultra Clear Glass, Screen Printed Glass, Pattern Glass, Tinted Glass, Clear Glass, etc.

Chat Online

Leave Message

- Product Introduction

- Technical Features

- Technical Parameters

- Customer Case

- In 2011 LandGlass introduced the Continuous Flat Glass Tempering Equipment to satisfy the increasing demands for tempered glass in the household appliances and solar markets. Because of its design, the line guarantees a stable operation and outstanding product quality.Thanks to this leap in quality, our Continuous Flat Glass Tempering Equipment had been installed in the leading international glass processing companies in 2012.This type of furnace is configured with forced convection units at its front end and can temper off-line low-E and screen printed glass rapidly and evenly..

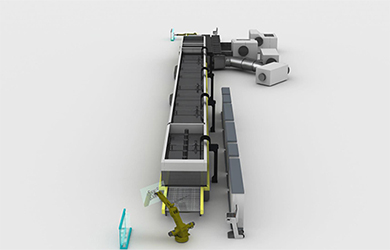

AirStreamTM Radiation Heating plays a supportive role during the process. Compressed air is injected into the heating furnace to aid the heating process of the top surface of the glass, which ensures heating uniformity for on-line Low-E glass, and other glass types.

JetConvection PlusTM Convection heating plays an important role during glass heating. Air is heated in the JetConvection chamber inside the heating furnace and is blown onto the glass surfaces. Air is then recirculated and recirculated by the convection blowers into the JetConvection chamber. LandGlass Jetconvection technology enhances the quality of the final product and increases productivity by ensuring an even heating, while minimizing production costs.

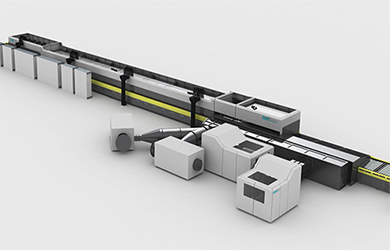

LD-AL JetConvection PlusTM Continuous Flat Glass Tempering Equipment adopts JetConvection PlusTM and AirStreamTM heating technologies. Glass tempered by this tempering equipment is suitable for flat glass for architectures, furniture, household appliances and solar markets. The glass that can be tempered includes: on-line and off-line Low-E (E=0.03)glass, extra ultra clear glass, screen printed glass, pattern glass, tinted glass, clear glass, etc. - 1. Longer heating and tempering sections ensure that glass sheets can be heated to the correct temperature and that it can be tempered and cooled quickly without oscillation.

2. The flexible driving speed control, selects the right speed for each of the stages of the process. The user can choose between logic servo controlled continuous mode or complete continuous mode according to the size of glass sheets.

3. Continuous running blowers ensure energy savings.

4. Glass doesn’t oscillate inside the heating section, what minimizes quality defects such as white haze, scratches, waviness, etc.

5. Continuous tempering technology ensures much higher productivity, suitable for tempering large volumes of flat glass sheets for the architectural, furniture, household appliances, automotive and solar industry markets.

6. Equipped with JetConvection heating system, it can temper on-line and off-line Low-E (E=0.03) glass, extra ultra clear glass, screen printed glass, pattern glass, tinted glass, clear glass, etc.

Productivity is calculated on 4mm clear glass with 100% loadage. Actual productivity is subject to glass types, sizes and loadage. Not all types are listed here due to limited space.LD-AL JetConvection Plus Continuous Flat Glass Tempering EquipmentTypes Max.dimensionMin.dimensionGlassthicknessProductivity(m2//h)Installedcapacity(KVA)A1225LJ+ 1200X2500 100X350 3-6/4-8 295 1600 A1230LJ+ 1200X3000 100X350 3-6/4-8 306 1600 A1525LJ+ 1500X2500 100X350 3-6/4-8 357 2000 A1530LJ+ 1500X3000 100X350 3-6/4-8 368 2000 A1625LJ+ 1600X2500 200X350 3-6/4-8 388 2500 A1630LJ+ 1600X3000 200X350 3-6/4-8 398 2500 A1730LJ+ 1700X3000 200X350 3-6/4-8 418 3000 - Company

Kuk Young G&M LocationKorea,East Asia Company ProfileEstablished in 1959, KUKYOUNG has a long history more than 40 years. As a senior enterprise in Korea, it's always leading the trend in glass processing industry. Up to this day, KUKYOUNG has developed to a big enterprise who involves 11 fields, such as tempered glass, laminated glass, revolving glass doors and so on. Furnace TypeLD-AL JetConvection Continuous Flat Glass Tempering Equipment Main ProductsDouble glazing glass, heat-tempered glass, insulated glass, laminated glass, bullet resistance window glass, curved window screen laminated glass, soundproof glass, electromagnetic shielding glass and fire resistant glass,etc.